For a brand to stand out in the competitive stationery market, the transition from stocking generic goods to offering a curated, proprietary product line is a pivotal milestone. The art supplies industry is no longer just about utility; it is about the sensory experience of the artist and the visual identity of the brand providing the tools. When businesses look to scale their offerings, seeking professional custom color colored pencils OEM solutions becomes the most effective strategy to ensure quality control while maintaining a unique market position.

In the world of fine art and professional illustration, the “feel” of a pencil—its laydown, its blendability, and its pigment density—determines whether a customer becomes a lifelong advocate or a one-time buyer. Original Equipment Manufacturing (OEM) allows a brand to bypass the astronomical costs of building a factory while gaining full control over the chemical composition and aesthetic design of their products. This partnership between brand and manufacturer is a delicate balance of chemistry, forestry knowledge, and logistics.

The decision to develop a custom line involves more than just picking colors from a catalog. It requires a deep dive into the nuances of lead formulation, wood casing durability, and the environmental ethics of the supply chain. For brands targeting professional artists, high-end gift markets, or educational institutions, the ability to customize every aspect of the pencil—from the Pantone-matched barrel to the specific hardness of the core—is what builds true brand equity.

The Anatomy of a Premium Colored Pencil Core

The core of a colored pencil is its soul. Unlike graphite pencils, which rely on a mixture of clay and carbon, colored pencils are complex chemical compounds. When engaging in custom color colored pencils OEM partnerships, the first point of discussion is usually the binder. Most high-end pencils use either a wax-based or an oil-based binder system. Wax-based cores are known for their soft, creamy texture and ease of blending, making them favorites for portraiture. However, they are prone to “wax bloom,” a natural oxidation process that can leave a hazy film over the artwork.

Oil-based cores, on the other hand, are typically harder and hold a sharp point for much longer. They allow for intricate detail work and are less likely to break during heavy-handed use. A professional OEM partner will offer the flexibility to adjust the ratio of pigment to binder, ensuring that the final product meets the specific “lightfastness” requirements of the target audience. Lightfastness refers to how resistant the pigment is to fading when exposed to UV light over time, a critical metric for professional-grade supplies.

Beyond the binder, the quality of the pigment itself is paramount. Cheap fillers can make a pencil feel scratchy or produce dull, “chalky” colors. Premium OEM solutions prioritize high-pigment loads and finely ground minerals. This ensures that the color remains vibrant even when layered multiple times. For further reading on the technical evaluation of art materials, the ASTM D4236 standard provides the industry benchmark for labeling chronic health hazards, which is a mandatory consideration for any brand entering the US or European markets.

Sourcing Sustainable Casings and Wood Quality

The wood that encases the core is just as important as the lead itself. In the manufacturing process, the wood must be stable enough to protect the fragile core from internal shattering during shipping, yet soft enough to be sharpened easily without splintering. Traditionally, Incense Cedar from the United States has been the gold standard for high-end pencils because of its straight grain and pleasant aroma. However, as global demand increases, many brands are looking toward sustainable alternatives.

Basswood and Linden wood are popular choices for mid-range to high-end custom color colored pencils OEM projects. These woods provide a consistent sharpening experience and take paint and lacquer finishes exceptionally well. When selecting a manufacturer, it is vital to verify their commitment to sustainable forestry. A brand’s reputation can be significantly bolstered by ensuring their products are certified by the Forest Stewardship Council (FSC), which guarantees that the timber is harvested responsibly.

The manufacturing process involves “slatting,” where the wood is cut into thin blocks, grooved to hold the leads, and then glued together in a sandwich-like fashion. If the glue is of poor quality or the grooves are misaligned, the lead will be off-center. An off-center lead is the primary cause of frequent breakage during sharpening, a common complaint among artists. High-quality OEM services utilize precision machinery to ensure the lead is perfectly centered every time, reducing waste and increasing customer satisfaction.

Comparison of Material Choices for Custom Pencils

| Feature | Wax-Based Core | Oil-Based Core | Water-Soluble Core |

|---|---|---|---|

| Texture | Soft and Creamy | Hard and Precise | Smooth/Transforms to Ink |

| Best For | Blending and Layering | Detail Work and Outlining | Mixed Media/Watercolor Effects |

| Durability | Medium (Prone to breaking) | High (Resistant to pressure) | Medium (Sensitive to moisture) |

| Sharpening | Requires gentle touch | Holds a fine point well | Standard sharpening |

| Common Issues | Wax Bloom over time | Requires more effort to blend | Accidental smudging if wet |

Customization and Brand Identity Design

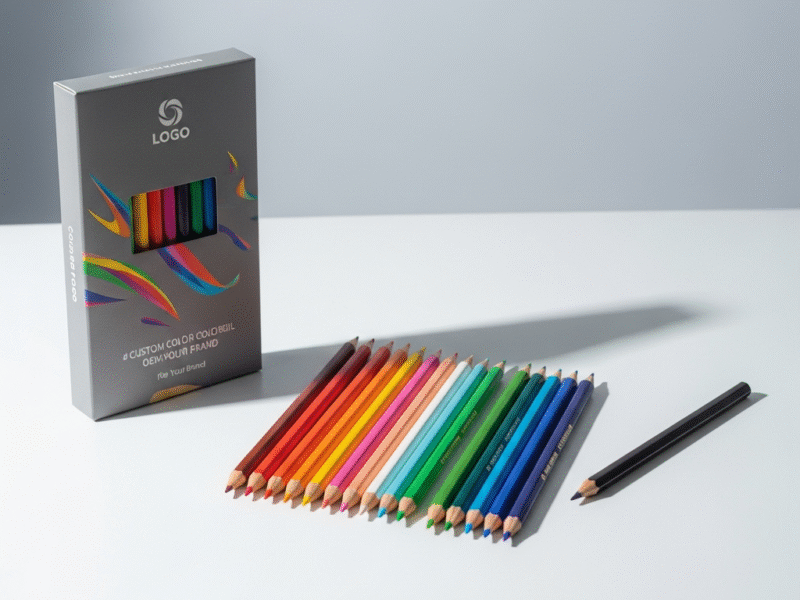

One of the most exciting aspects of working with custom color colored pencils OEM providers is the level of aesthetic customization available. A pencil is a tactile object, and its exterior finish communicates a brand’s value immediately. For a luxury brand, a matte finish with gold foil stamping might be appropriate. For a modern, minimalist brand, a natural wood barrel with a simple UV-printed logo might be the better choice.

The “dip-end” (the painted cap at the end of the pencil) serves a functional purpose as well as a stylistic one. It allows the artist to quickly identify the color they need. High-quality OEM partners can match these dip-ends to specific Pantone Matching System (PMS) colors, ensuring that the brand’s visual identity is consistent across all marketing materials and the product itself.

Packaging is the final frontier of the OEM process. Whether it is a sleek tin box, a rustic wooden case, or an eco-friendly recycled cardboard tube, the packaging must protect the pencils while telling the brand’s story. Custom inserts, such as foam or plastic trays, are used to prevent the pencils from rattling and breaking during transit. Professional manufacturers will offer prototyping services for both the pencils and the packaging, allowing you to hold a physical sample before committing to a full production run.

The Logistics of OEM: MOQs and Lead Times

Understanding the business side of custom color colored pencils OEM is crucial for a successful launch. Most factories operate on Minimum Order Quantities (MOQs). For a fully customized product—where the core formula and the barrel colors are unique to your brand—MOQs can range from 5,000 to 20,000 units per color or set. This is because setting up the machinery for a custom run requires significant time and material waste during the calibration phase.

Lead times in the stationery industry can be surprisingly long, often ranging from 45 to 90 days. This timeline accounts for raw material sourcing, production, quality testing, and packaging. Shipping also plays a major role; since pencils are dense and heavy, sea freight is the most common method of transport, which can add another 30 to 45 days depending on your location. Brands must plan their inventory cycles at least six months in advance to ensure they don’t run out of stock during peak seasons like “Back to School” or the holidays.

Working with an experienced OEM partner also means having a teammate in quality assurance. A reputable factory will have in-house testing labs to check for “lead strength” (how much pressure the core can take before snapping) and “sharpening performance.” They should also provide certificates of compliance for safety regulations in your target market, such as the CE mark for Europe or the UKCA for the United Kingdom.

Trends Shaping the Future of the Stationery Market

The demand for custom color colored pencils OEM is being driven by several macro-trends in the consumer market. First is the rise of the “Adult Coloring” movement, which transformed colored pencils from simple school supplies into stress-relief tools for adults. This shift created a massive market for “artist-grade” sets that are more expensive but offer much higher quality. Brands that can bridge the gap between affordable pricing and professional performance are currently seeing the most growth.

Another significant trend is the move toward “Plastic-Free” and “Zero-Waste” products. Consumers are increasingly wary of plastic-wrapped pencil sets. This has led many brands to request OEM solutions that utilize FSC-certified wood, water-based lacquers (instead of solvent-based paints), and plastic-free packaging. Demonstrating environmental responsibility is no longer a niche marketing tactic; it is a requirement for modern brand longevity.

Finally, there is a growing interest in specialized “Skin Tone” and “Nature” themed sets. Rather than a standard 12-color rainbow, brands are finding success by offering curated palettes that cater to specific artistic needs. A custom OEM partner can help you develop these unique color ranges, allowing your brand to serve underserved communities and artistic niches that generic brands often overlook.

Navigating the Partnership: How to Choose a Manufacturer

Choosing the right partner for your custom color colored pencils OEM journey is a long-term commitment. It is not just about who offers the lowest price per unit; it is about who offers the best communication, consistency, and ethical standards. When vetting potential manufacturers, ask for samples of their existing work. Test these samples rigorously. Do they sharpen cleanly? Does the core crumble? Is the color laydown consistent?

Communication is often the biggest hurdle in international manufacturing. Ensure your partner has a dedicated account manager who understands your technical requirements and can provide regular updates on the production timeline. If possible, conduct a third-party factory audit. This ensures that the facility adheres to fair labor practices and maintains the quality standards they claim to uphold.

Ultimately, the goal of an OEM partnership is to allow you to focus on what you do best: marketing and building your brand. By outsourcing the complex science and logistics of manufacturing to experts, you can ensure that every pencil bearing your logo is a testament to quality and craftsmanship. The right manufacturing partner doesn’t just make pencils; they help you craft the tools that will inspire the next generation of artists.

In conclusion, the path to a successful private-label stationery line is paved with detailed decisions regarding core chemistry, wood sourcing, and aesthetic design. By leveraging a custom color colored pencils OEM model, brands can provide exceptional value to their customers while maintaining the flexibility to adapt to changing market trends. Whether you are aiming for the professional art market or the burgeoning hobbyist sector, the quality of your manufacturing partner will be the foundation upon which your brand’s success is built.

Related Reading

- Top OEM Options for Custom Colored Pencils

- Custom Colored Pencils for Brands: Boost Your Promotion

- 24-Color Colored Pencils OEM: Quality for Artists

- OEM Pastel Pencils for Art Brands

- Customize Your Pastel Colored Pencils for Unique Expression

- Retail-Ready Colored Pencils Packs: Your Buying Guide

- Affordable Colored Pencils for Retailers: Top Picks

- Hong Zin Tai OEM Minimum Order Quantity Explained